Lots of reading and talking about sustainability and the Circular Economy. It’s time to start moving the first steps; so take a break, mute your phone and get ready. We are going to explore some useful tools that help to review your actual business model by accelerating the journey towards circularity and sustainability.

Whatever the business you are in, whatever the kind of products or services your company creates or sells, whatever what you think about Circular Economy, if you did not walk the first steps already in that direction, now it’s the time to revise the way you and your company are making money through the lens of sustainability.

Every company in the upcoming years needs to be in a sustainable business, under the penalty of constantly losing market share and competitiveness

However, transforming the business in such a sense is definitely not trivial and requires energies and dedicated resources (time and money); well, fortunately we are not starting from a blank page.

There are already available some great tools that can be used for articulate a strategy in that direction, which are the focus of this article:

- Sustainable Loops

- Sustainability SWOT Analysis

- Sustainable Business Model Canvas

Sustainable Loops

We like to think to this first tool more as a thinking framework than a real tool, which can be used in initial stages when brainstorming on sustainability applied to new or existing businesses.

In literature, these loops are defined as:

- “Slowing Loops“is about prolonged use and reuse of goods over time, through design of long life goods and product life extension;

- “Closing Loops” is about reuse of materials through recycling

- “Narrowing Loops” is about reducing resource use associated with the product and production process

For each loop, current business model needs to be assessed and possibile alternatives must be thought according to underlying sustainable logic and meaning.

Slowing Loops

Slowing loops means to ideate long-life products and to design for product-life extension; products must be thought to last as much as possible so that they consume less energy and resources, while increasing profitability. Really?! How this can be possible?

To some companies, the ones that are still very much entrenched in the Linear Economy models, this may sound strongly counter-intuitive:

“If today I design my products to last more, I will sell less of them tomorrow, and consequently my revenues will decrease over time as well, isn’t it?”

Actually, companies should start selling Sustainable Products with attached dedicated services such as support and maintenance, refurbishment or re-manufacturing or, completely changing their underlying business logic by embracing PSS (Product-Service-System) or SaaP (Service as a Product) approaches (e.g., selling not only wash machines, but also washing hours – i.e. the service of washing clothes without having customers owning a machine).

Very well-known examples are:

- selling lightning instead of light bulbs (i.e., Philips),

- flying hours instead of aircraft engines (i.e. Rolls-Royce),

- renting building construction machinery (i.e., Caterpillar).

This is the biggest cultural shift to overcome for companies who are serious in embarking in the circularity journey.

Instead of designing products whose property is transferred to customers, it remains with the producer. This opens up to new business models that require organizations to design products for:

- Reliability and Durability

- Ease of Maintenance and Repair

- Upgradability and Adaptability

- Standardization and Compatibility

- Disassembly and Reassembly

Closing Loops

Closing loops are about reducing, reusing, recycling natural resources in its broader sense. It’s all about trying as much as possible to decouple and detach production from natural resource utilization and, regarding energy consumption, to make mainly (if nottotally) use of renewable ones.

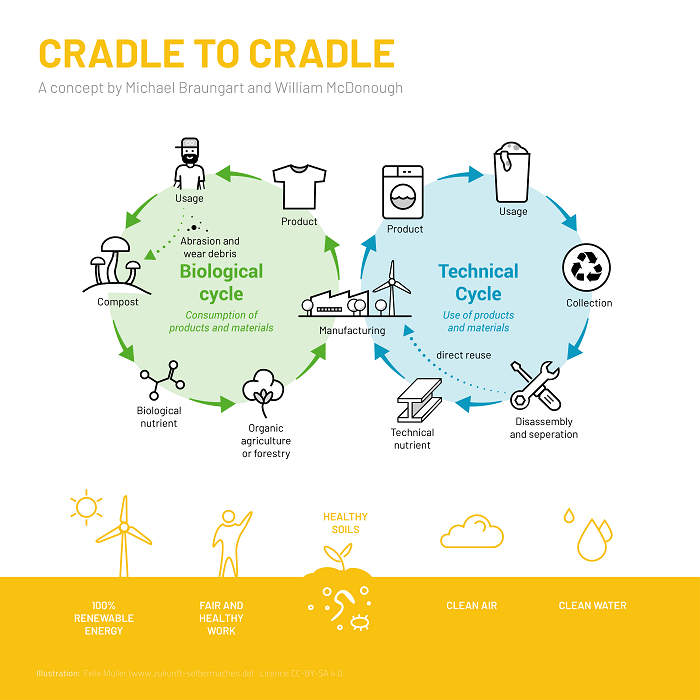

According to McDonough and Braungart and their seminal book Cradle to Cradle, any products, in order to reduce waste and pollution, must be designed by using materials as ingredients specifically thought for two precise “metabolisms“: Biological or Technical.

Products designed to be part of the biological cycle are made of natural resources that are used, re-used and recycled, until they reach the end of their life and, thanks to their biodegradability, they can be disposed to come back to the natural environment (see compost).

Here we have tons of examples of companies recycling materials from their own production or textiles, natural fibers or even any organic waste arriving from other companies’ industrial cycles that can be reused to give life to brand new products. Circularity of resources is key.

On the other side, products designed for the technical cycle are made of any resource that is not biodegradable and cannot come back to the natural environment. For these products we need to make wise use of materials using, reusing and recycling them as long as possible.

An example comes from companies that are selling construction machines and equipments. They rent refurbished or re-manufactured products (which are very expensive) at a significant lower price with a certificate of “like-new-product” that covers the same warranty time duration of brand new products. This is possible because they also give support and specific maintenance to keep their products up and running with high quality standards, knowing that their products will be sold again and again to other customers, making the business model very profitable.

Of course, there are some complexities that need to be addressed; one out of all is reverse logistics. Products rented to customers need to be tracked in terms of usage, time of rent and, applying for example AI predictive maintenance algorithms, producers need to pick those products back to factory to be tested, disassembled, cleaned, reconditioned, and, for damaged or excessively worn parts, proceed with their replacement. Once finished, the machine or equipment will be sent back to the customer.

Once materials belonging to the technical cycle finally reach their very end of life, some strategies are still possible such as recovering chemical constituents, breaking them down to original raw core components.

Narrowing Loops

Narrowing loops are referring approaches that, actually, have been already applied extensively since decades: reducing usage of materials, energy, time (in general wastes) is, to mention one, the key concept behind Lean practices applied to manufacturing.

Unfortunately, during the course of past years, those concepts has been mainly applied, though, to linear economy, and not to make the good of the planet

Increasing production efficiency while decreasing costs by applying narrowing loops in that context, inexorably brought the whole system to increase products creation that actually led to further worsening the environmental situation, actually increasing pollution and waste.

Thus, narrowing loops applied to sustainability, must be taken into consideration as a strategy to reduce general planet resources consumption and to even more enhance circularity.

The Sustainability SWOT Analysis

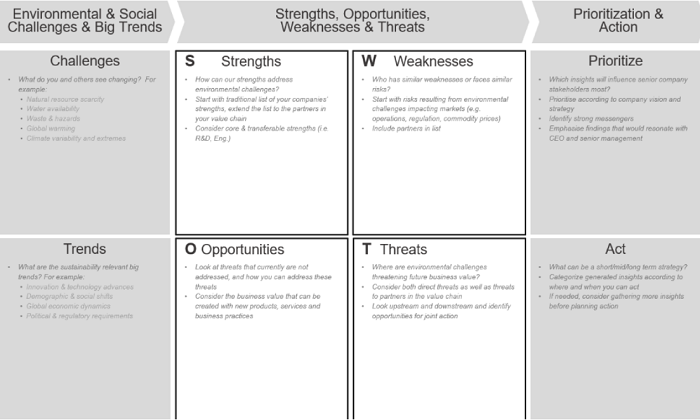

The SWOT Matrix (Strengths, Weaknesses, Opportunities, Threats) is an analytical tool used to evaluate companies’ competitive position, in order to develop strategic planning by assessing internal and external factors, as well as current and future potential.

It has been created by two Harvard Business School professors in early 1950s, when problems related to sustainability were yet to come.

This tool is actually so powerful that, by tweaking it a bit, can be of great help also to investigate how to make a company’s operations more sustainable. The one below reported is an example of how to change this tool in that sense, which can be downloaded here.

As it is explained by the creator here, the analysis can be conducted by following these three steps.

First (Challenges and Trends), brainstorming on environmental and social challenges and big trends and how they can impact the company and its business.

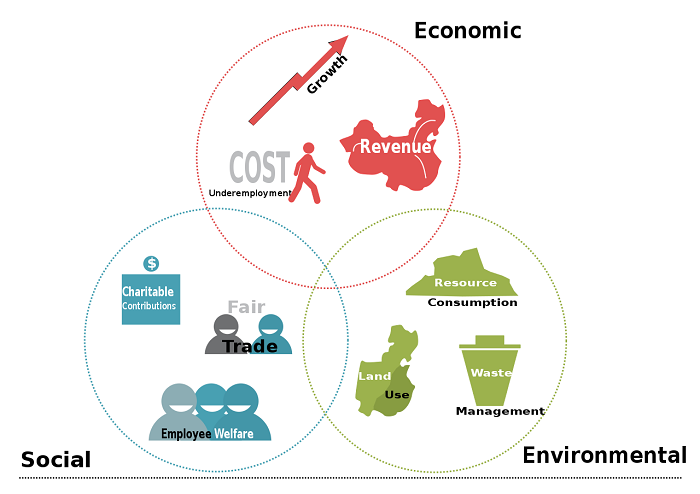

Second, conduct the classical SWOT analysis but by keeping in mind the triple bottom line (People, Planet, Profit).

Source: https://en.wikipedia.org/wiki/Triple_bottom_line#/media/File:Triple_Bottom_Line_graphic.svg

Third (Prioritisation and Action), review ideas and insights emerged from the analysis and decide next steps to make them real and viable for company’s business.

Sustainable Business Model Canvas

The Business Model Canvas is a famous strategic management tool initially proposed in 2005 by Alexander Osterwalder. It is used for developing new business models or documenting existing ones. It essentially covers three key areas: firm’s (or product) value proposition and customers relationship, key activities and partnerships and the financial perspective.

This powerful tool should be used anytime a company want to explore new products and services, or to assess its current business model to improve and develop it furthter.

The nine building blocks are as follows:

- Value Proposition: the unique solution which addresses a specific customer need

- Customer Segments: target group of people or companies

- Customer Relationships: this explain the kind of customers’ relationships and interactions

- Channels: how the communication will happen and what are the touch points

- Key Activities: list of key tasks and activities to execute to reach the business purpose

- Key Resources: main resources and inputs needed to carry out the key activities

- Key Partners: external actors (suppliers, partners, etc.) that will help with key activities and resources

- Cost Structure: cost associated with the business model under analysis

- Revenue Streams: how the company will generate money through this business model

In 2005 problems related to sustainability were already known and discussed (see 1992 Earth Summit in Rio De Janeiro) even if they were not as hot as today and it’s not surprise that Osterwalder did not dedicate any block or section to such a topic.

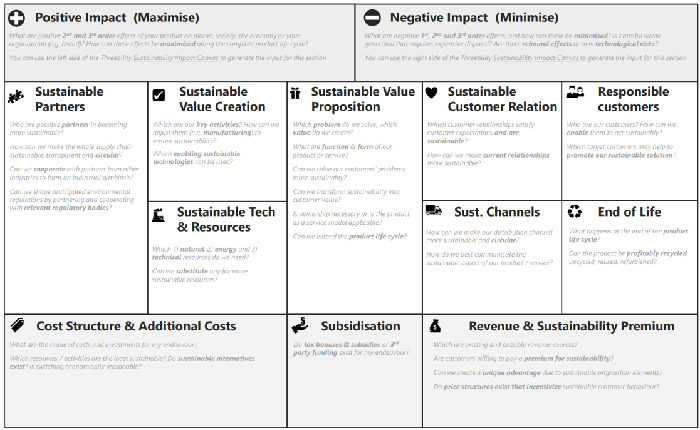

Fortunately, a Sustainable Business Model Canvas has been lately created.

This tool effectively guides any companies in defining a new business model or reviewing their current one, by using the lens of sustainability.

First of all it added two specific blocks: Positive and Negative Impacts.

The first one explores what positive effects the company could produce, not only to its business, but also on the planet, society, and the overall economy. The latter identifies what negative consequences can be generated and how they can be minimized (if not eliminated at all).

Then we have the same above mentioned nine blocks, but their descriptions is always preceded by the suffix “Sustainable” and each block is then analyzed with such a sensitivity.

For example, when it comes to resources the discussion focuses on water, energy, etc. and how the consumption can be minimized while maintaining profitable the business. When it comes to key partners the analysis should be around how to choose the most transparent and the ones that already have in place circular practices.

Perhaps the most important one is the Sustainable Value Proposition, which explores how the business model can be sustainable and related products can take into account the aforementioned Sustainability Loops.

For a detailed description on how to use this canvas, have a look here.

To conclude, there’s no one business that already today cannot be sustainable: pressure from customers, employees and investors is constantly increasing.

Sustainable Loops, Sustainability SWOT Analysis and Sustainable Business Model Canvas, are three easy to use and smart tools which can help any companies to steer their business towards more circularity and respect of our planet and communities.